Technology

FROM NATURE

FOR NATURE

Biodegradable plastics will completely disappear from the environment.

100%

NON-FOOD!

PLA (Poly Lactic Acid) is a thermoplastic. It is bio-based and biodegradable and can replace petroleum based plastics like polypropylene (PP), polyethylene (PE), polyethylene terephthalate (PET) or polystyrene (PS). PLA consists of L-lactic and some D- lactic acid as building blocks. Today PLA is produced from lactic acid which is produced from sugars or starchy biomass (1st generation L-lactic acid). Therefore production costs are still too high for L-lactic acid and PLA to compete to polyethylene or even polystyrene based on fossil fuel.

To reduce significantly the production costs low cost raw materials have to be used, like cellulosic waste and a process which most efficiently converts these feedstocks to the product, L-lactic acid (2nd generation L-lactic acid). Such technology development has been initiated and carried out by Direvo Industrial Biotech GmbH in Cologne. BluCon Biotech GmbH now drives the commercialization of the BluCon technology by modern strain and bioprocess engineering.

The unique technology of BluCon Biotech GmbH enables consolidated bioprocessing (CBP) of lignocellulosic feedstocks to L-lactic acid using thermophilic bacteria in a one step process. Our first aim is to exclusively use cheap non-food cellulosic or lignocellulosic feedstock and to create a 2nd generation L-lactic acid process, thus to convert waste to value. Our second aim is to provide a basis for replacing fossil oil based plastic which is not biodegradable and is accumulating in our world creating huge environmental problems.

Our BluCon process can use a broad variety of feedstock materials from agriculture, like grasses (straw, corn stover, bagasse, miscanthus, switchgrass, sorghum), wood type materials (poplar, spruce, cotton stalks) or from industrial processes ( cellulosic waste from paper recycling or pulp&paper production, Dried Distillers Grains with Solubles (DDGS), beet pulp) to produce L-lactic acid, the building block for PLA.

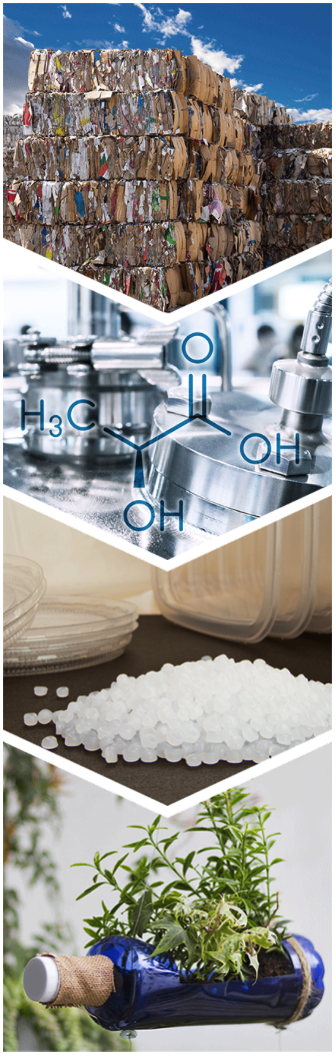

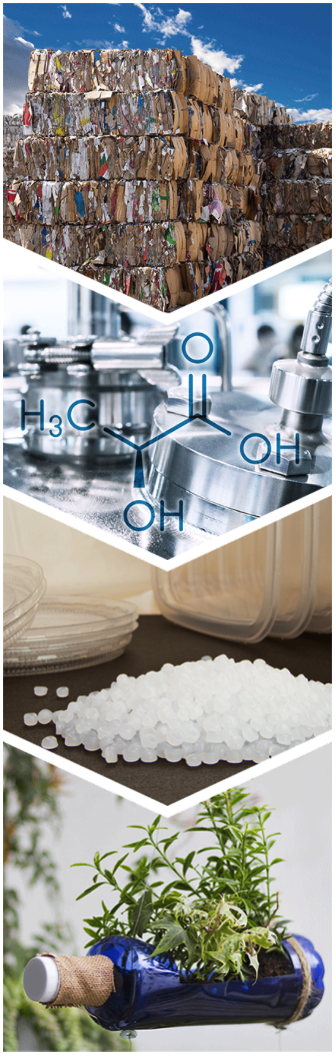

VALUE CHAIN:

BIO-REFINERY-CONCEPT BLUCON

1. Feedstock

- Residues paper recycling

- Agriculture residues

- No competition to feed/food market

2. L-lactic acid production

- Robust process

- Feedstock flexibility

- Ability to convert C5 and C6 sugars

- No additional enzymes

- Worldwide application

- Target: cost competitiveness compared to PET

3. Polymerization to Poly Lactic Acid

- Collaboration with TJL Biomaterials Co. Ltd. Shanghai

4. Final Poly Lactic Acid Product

- Wide range of applications

- sustainable

- biobased

- biodegradable

BluCon Biotech GmbH is a company that has developed a unique technology for producing L-lactic acid at low costs. It uses proprietary bacteria to digest lignocellulosic biomass and produce lactic acid, the building block of PLA, in one bioreactor. The innovative fermentation process developed by the company directly converts these raw materials into L-lactic acid. This is the first time this has been done in the world. This technology has the potential to make bioplastics such as poly lactic acid (PLA) competitive with fossil-based plastics and can help reduce the amount of non-degradable plastic waste by replacing fossil based plastics with biodegradable, sustainable products. BluCon's technology uses agricultural and industrial residues instead of sugars, which avoids competition with the food chain. The technology has a significant positive impact on the environment, carbon footprint and circular economy, and aligns with the United Nations Sustainable Development Goals (SDGs).

SITEMAP

OUR OFFICE

BluCon Biotech GmbH

Nattermannallee 1

50 829 Cologne

Email: blucon@blucon-biotech.com